With 15 dedicated silicone mold production lines, we specialize in the design and manufacturing of silicone baking molds.

Injection molding employs high pressure and elevated temperature to force silicone into molds. This process delivers exceptional precision, consistency, and design complexity, making it ideal for high-volume production.

Household silicone molds typically feature smaller dimensions and are constructed from pure silicone material. Commercial-grade large-format molds generally incorporate fiberglass reinforcement (fiberglass + silicone) to enhance tear resistance and maintain dimensional stability.

✔Material Safety ✔Non-Stick Performance ✔Thermal Stability ✔User-Friendly Design

ABOUT US

Fengyang Jiasong New Material Technology Co., Ltd.

As a factory established in 2014,we have much experience in making silicone kitchenware,also have good management of quality,lead-time and reasonable price.At first,Jiasong only focused on domestic market,and made for local trading companies.In 2016,Jiasong started business of export.

Established in 2014

Started business of export

Exporting countries

More than 150 workers

Output value of 200 million

OUR SOLUTION

Benefited from continuous efforts on positive performance in market,being faithful to contract,qualified products,and competitive price,we succeeded in cooperating with many famous brands all over the world,and being one of their long-term suppliers.

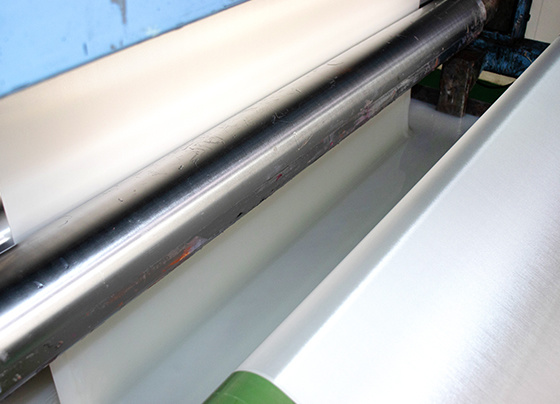

COATING

Applying the silicone layer onto a surface using methods of coating on the fiberglass basics, and making to the silicone rolls.

MOLD PRESSING

Shaping materials (plastics/metals) using heat and pressure within a mold cavity. Ideal for producing high-volume components with consistent geometry.

INJECTION

Forcing liquid silicone into a mold to solidify into complex shapes.

EXTRUSION

Pushing heated silicone through a die to create products.

FLATHENING

Compressing rolled materials (silicone sheets) to achieve uniform thickness.

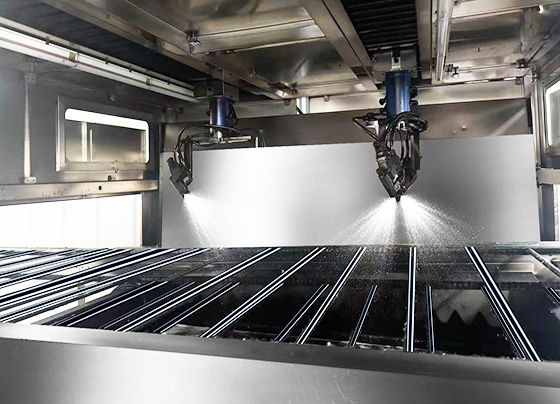

SPRAY

Atomizing liquids silicone raw material onto surfaces via air pressure.

CUTTING

Separating the silicone roll materials using dies.

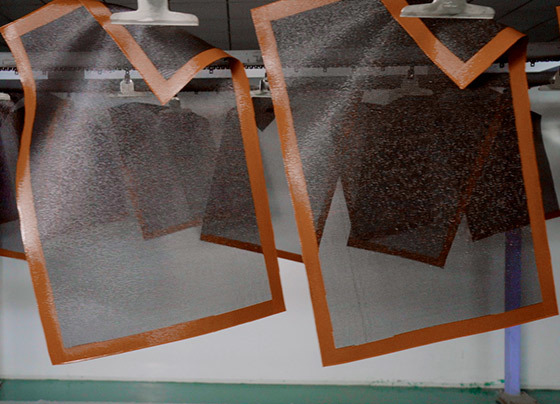

PRINTING

Transferring silicone/designs onto substrates via screen methods.

DIPPING

Immersing the silicone mats' edges in liquid silicone for seal.

OUR CLIENTS

Our commitment to excellence has enabled us to build strong partnerships with renowned brands worldwide,making us a trusted supplier in the market.We prioritize customer satisfaction by offering competitive prices,timely delivery,and a wide range of innovative kitchenware solutions. With a keen eye on market trends and a dedication to superior craftsmanship,we strive to provide stylish and reliable silicone kitchenware that enhances the cooking experience for households globally.

The Pros and Cons of Using Silicone Leather Fabric: A Comprehensive Guide

The Pros and Cons of Using Silicone Leather Fabric: A Comprehensive Guide Silicone leather fabric, an innovative alternative to traditional leather, has garnered significant attention in various industries, from fashion to automotive upholstery. As we explore the pros and cons of this synthetic material, we aim to provide a thorough understanding of its characteristics, benefits, drawbacks, and ap

Understanding the Versatility of Adhesive Backed Silicone Sheets in Rubber Manufacturing

Adhesive backed silicone sheets are specialized materials combining the unique properties of silicone with the convenience of a pre-applied adhesive layer. Silicone, known for its elasticity, durability, and resistance to extreme temperatures, serves as an excellent choice for a variety of applications in the rubber industry. When combined with an adhesive backing, these sheets become not only fun

Choosing the Right High Temperature Silicone Rubber Sheet for Your Project

Choosing the Right High Temperature Silicone Rubber Sheet for Your Project Table of Contents Understanding High Temperature Silicone Rubber Benefits of High Temperature Silicone Rubber Sheets Applications for High Temperature Silicone Rubber Sheets Key Factors to Consider When Choosing Silicone Rubber Sheets Temperature Resistance Thickness and Density Chemical Resi